Supply chain management techniques are always up for debate, but the demands are common: contractors want to save time, effort, and money when it comes to deliveries. In the current market with a tight supply environment, contractors must go beyond their original practices to meet the demand and opportunity. While large corporations have a wider set of options like chartering ships or booking bulk vessels, small to midsized organizations deal with less buying volume. Therefore, contractors need to look to more innovative strategies and collaborations with partners in their supply chain to deliver supplies on time and efficiently.

There are ways to reduce downtime, increase efficiency and raise profit margins, they just need to be applied the right way. Here are 4 things about deliveries you may not have considered:

Bulk Orders

Contractors try to put in daily orders to decrease storage, but this technique has its drawbacks. Daily ordering can expose you to supply chain issues and cause workflow issues if your necessary supplies don’t arrive on time. Paying your subcontractors and workers to wait for supplies to arrive will erode your profit margin quickly.

Examine your project schedule and come up with a comprehensive material management strategy that aligns with the rest of your suppliers so you can pre-plan deliveries. There will be a rise in material shortages which minimizes work downtime and give you more volume discounts due to the size of your orders, rather than small daily orders that breed fewer savings.

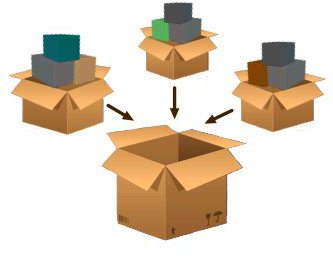

Talk To Your Supplier About Kitting

Many contractors simply receive the ordered materials when they need them. This makes sense, but if you can actually request your distributor to make customized packages for each section or part of your project that can help with organization.

This is called ‘kitting’, and can really minimize excessive time spent handling materials at your construction sites. When your supplier packages materials for you and organizes them, this gets rid of the extra time and money spent on-site sorting. This can really boost your project savings and minimize overall costs. Kitting is also great for maximizing the efficiency of your business because then you can create more freedom and time to secure new contracts and less time doing the busy work of sorting and moving materials.

Utilize Data and Analytics

With technology at our fingertips, using historical data and advanced analytics is a no-brainer, literally. When companies use data and analytics to prioritize certain materials, they can ensure the right product organization in a supply chain. Also, this helps suppliers work on big orders of a few items instead of small orders which affects the delivery time. Anything that’s not ordered or not needed at the current time will impact the profit margin and increase the holding cost and also limit the opportunity to work on more projects.

Ask for Alternates or Substitutions Early and Often

When a project manager discovers a lead time will take longer than they expected for a material, or there’s a significant spike in cost, the contractor or project manager can opt for a substitution, if possible. If there’s an increase in cost, the substitution can note the cost increase of the original item. If the substitution is denied, the contractor will be more inclined to make a claim based on the unavailability.

There are several ways to increase efficiency and profit margin while limiting downtime. Speak to your suppliers and see if you can work together to move more efficiently and productively.

Keywords: Supply Chain, Construction Management, Construction Delivery(ies), Logistics Management